Ruby Balls

BETSA® ruby balls sample showing their perfect spherical shape and their wide size distribution from 3 to 50μm

BETSA® has provided the High pressure community with ruby balls for in situ pressure measurement for over 20 years.

Corindon - Aluminium Oxide Doping 3600 ppm (Cr3+): Al2O3:Cr3+

- balls Ø3 µm to Ø50 µm

OUR REFERENCES

[RUB10]

Seat and Rocker

Pieces & replacement parts for MDAC

It's parts are adapted for the MDAC and the diamond anvil. They are manufactured according to the need for pressure and temperature in Tungsten Carbide, Titanium Diboride or Zirconia

For the seats and rockers of our DACs, we offer materials adapted to the experiments, for very low and very high temperatures and also experiments in magnetism.

The seats are interchangeable between DACs of the same family, you can also have several seats with anvils for a single DAC

OUR REFERENCES

Support plate seat Tungsten carbide [S-WC]

Support plate seat dedicated for Very High Temperature (1200°C continuous) [S-TIB]

Support plate seat dedicated for amagnetic at Very High Temperature [S-ZRO]

Support plate seat dedicated for Very High Temperature (1200°C continuous) [S-TIB]

Support plate seat dedicated for amagnetic at Very High Temperature [S-ZRO]

Screws and Junction

These elements serve as a junction and connection for Membrane DACs [MDAC].

Small in size, these Screws, Olives and junctions allow connection at 200 Bars in a wide temperature range.

OUR REFERENCES

6 Sides screw BETSA® [092 410]

Olive BETSA® [092 411 ]

Fitting right junction inconnel [092 430}

Membranes

BETSA® offers a wide range of membranes for [MDAC]

These are available depending on the environment of the experiment, low or high temperature and also in the non-magnetic experiment with a suitable material

OUR REFERENCES

- Membrane SOLDERED junction [MEMB-SO]

- Membrane SCREW junction [MEMB-SC)

- Membrane LATERAL junction [MEMB-LA]

- Membrane special [MEMB-SP] on demand

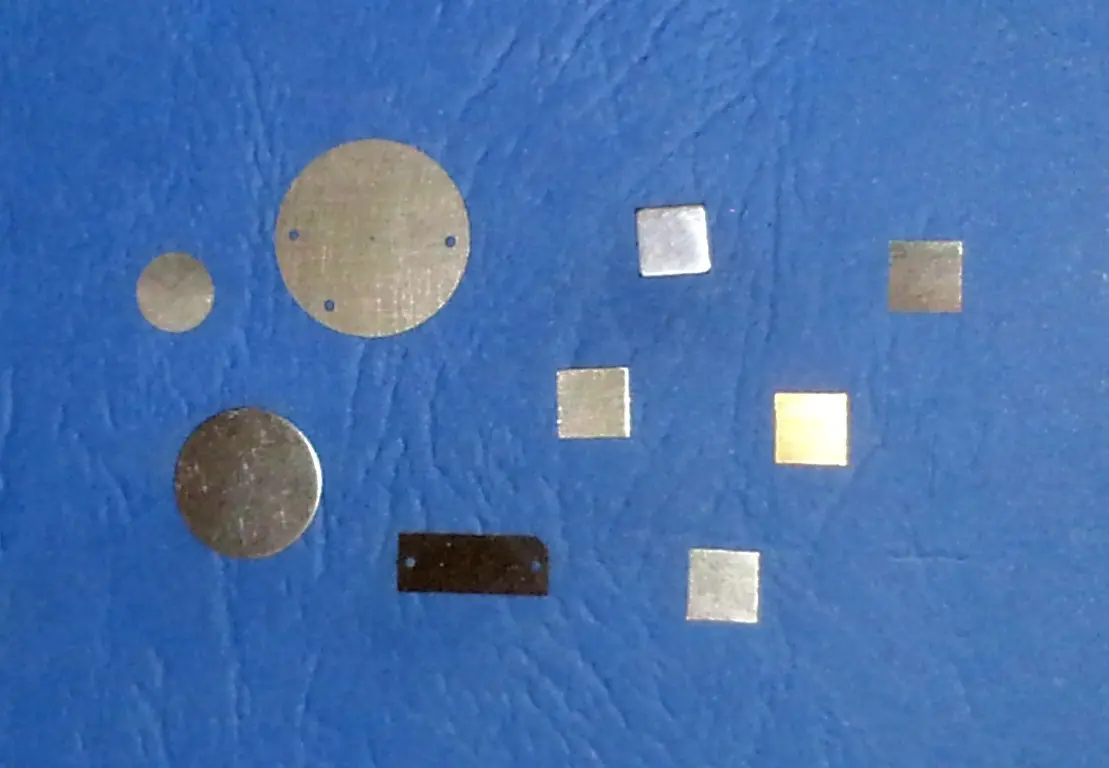

Gasket

BETSA® offers gaskets in different shapes, usually circular or square and thicknesses 150µm upt to 500µm.

The materials offered are stainless steel, copper berilium, rhenium and other inconels. Other materials such as copper 101, WC are possible.

We have all the following references in stock or on short notice

Know that it is possible to order dimensions and thicknesses on request

OUR REFERENCES

Gasket - stainless steel 301 - 200µm X Ø15mm [JT SS]

Gasket - stainless steel 301 - 200µm X Ø10mm [JT SS]

Gasket - stainless steel 301 - 200µm x 5,2 x 5,2mm [JT SS]

Gasket - stainless steel 301- 600µm x 5,2 x 5,2mm [JT SS]

Gasket - CuBe - 200µm x 5,2 x 5,2mm - Unannealed [JT CB]

Gasket - CuBe - 200µm x 8mm x 3mm - Unannealed [JT CB]

Gasket - CuBe - 200µm x 5,2 mm x 5,2mm - hardened 315°C-3h in vaccum [JT CB]

Gasket - Copper CuA1 99,99% - 200µm±10% x 5,2mm x 5,2mm±0,5 mm - Recuit [JT CU]

Gasket - Rhenium 99,98% - 150µm x 5,2mm x 5,2mm +/- 0.005" - Unannealed [JT RH150]

Gasket - Rhenium 99,98% - 200µm x 5,2mm x 5,2mm +/- 0.005" - Unannealed [JT RH200]

Gasket - Rhenium 99,98% - 200µm x 5,2mm x 5,2mm +/- 0.005" - Annealed [JT RH200 A]

Gasket - Rhenium 99,98% - 250µm x 5,2mm x 5,2mm +/- 0.005" - Annealed [JT RH250 A]

Gasket - INCONNEL X750 - 250µm x 5,2 x 5,2mm [JT IN]

Gasket - copper 101 - 200µm x 5,2mm x 5,2mm - Raw - Unannealed [JT CU]

Gasket - WC - 200µm x 5,2mm x5,2mm [JT WC]

We have the ability to make exotic shapes

Do not hesitate to ask us

Capillaries

The offered capillaries are used for pressure junctions between pneumatic drive systems and membranes.

The small size, weight, and portability of the [PDS] allow its use in a variety of environments.

OUR REFERENCES

(max 10M on one roll)

Capillary Inox 1/16” OD x 0,75mmID [CAP16 750]

Capillary Inox 1/16” OD x 1mmID [CAP16 1000]

Capillary Inox 1/32” OD x 0,25mmID [CAP32 250]

Capillary Inox 1/32” OD x 0,50mmID [CAP32 500]

Tubing Inox 316L 1/16" OD (PDS) |1156]

OUR REFERENCES For MEMBRANE assembly

Capillary Inox OD : 1/16” x ID : 1mm ; total lenght 5 CM [CAP16-X5]

Capillary Inox OD : 1/16” x ID : 1mm ; total lenght 5 CM - laser soldered - High Temperature [CAP16-X5-L}

Capillary Inox OD : 1/16” x ID : 1mm ; total lenght 30 CM [CAP16-X30]

Capillary Inox OD : 1/32" total lenght 30 CM between 2 capillary 1/16" 5CM [CAP32-X30] z

other are possible on demand

Micro-Valve

Micro-valves are essential to separate the Membranes from the pressure controller and keep the pressure constant up to 200Bars.

The BETSA®'s micro-valves are made of materials ensuring a long lifespan (assembly-disassembly), and are available to operate from 1K to 800K an also on no-magnetic experiments.

OUR REFERENCES

Micro-valve 2 SCREWS (inconel) [VAL-2SC]

Micro-valve 1 SCREW (inconel) [VAL-1SC]

Micro-valve 2 screws low temperature (inconel) [VAL-LOW]

Micro-valve 2 screws low temperature no magnetiv (Tytanium) [VAL-LOW A]

SPARES

Disc membrane micro-valve [092403]

Joint micro-valve [JMV]

Polished microvalve closing screw M4 [VPFM]

other are possible on demand

Diamond Anvils

BETSA® offers diamond anvils for cells of any shape, standard or conical, as well as windows.

BESTA® has several suppliers in order to offer the most suitable product according to the price of the moment and the availability of stocks, BETSA® also can propose the assembly, gluing and adjustment of your diamond anvils

OUR REFERENCES

Diamond Anvil: Type: Ia - IIa - IIac - IIas

Design: standard - Conical

Sides: 8 - 16

Height: depends on culet size

Bevel: no bevel - simple bevel 8°

Ø: 2,5 - 3,10 - 3,30- 4mm

X-ray aperture: 70° - 80° - 85° - 100°

Culet size: to define - 300µm x --µm

Oriented:(100)

Birefringence selection: standard - low - Ultra low

Raman fluorescence : standard - low - Ultra low

Measure your gasket thickness

The MEJ01 was designed to ease the measurement of the indented gaskets thicknesses.

There is no risk of deforming the gaskets with the steel points.

Mechanical features:

- Resolution: 0,001 mm - 0.00005”

- Mechanical aperture 6.35mm - 1/4”

- XY setting of the lower point.

- Interchangeable conical points.

- Conical point tip size: Ø 0.50 mm

- External sizes:

W= 65mm.

D=120mm.

H=190mm.

Others features:

- Switchable mm/inch.

- Zero setting.

- Setting limits and values.

- Digital Display, analogical mode and high

resolution.

- Full-screen LCD.

- Auto-off.

OUR REFERENCE

Measure your gasket thickness [MEJ01]

MDAC Washer

Compensation washers are used for the union between the membranes and the MDAC.

They are offered in several thicknesses to compensate the deformation of the membrane and are available in several materials

OUR REFERENCES

MDAC Washer for RT [092 115]

MDAC Washer for RT 3,3mm [095 204]

MDAC Washer for HT [097 009]

Guidance Dowel

The BETSA® design uses 4 Guidances dowels per DAC. They guide the movement on the Z axis with extreme precision.

BETSA® offers Guidances dowel in different alloys depending on the experience environment.

It is possible to make thermal and surface treatments to improve the operating conditions.

Guidance dowel in treated steel, high temperature inconel or Beryllium copper, of different length and Ø, with anti-oxidation, thermal or tefloning treatment. This is all that BETSA® offers for these MDACs.

The quality of rectification 1-3µm of these guidance dowels can lead, depending on the case, to an aid in disassembly after high temperatures or to obtain an accuracy of 0.1µm.

OUR REFERENCES

pige-guidance dowel (sold by 24 pieces) [901 008]

pige-guidance dowel microfral100 (sold by 24 pieces) [901 008 M100]

pige-guidance dowel microflon M2 (sold by 24pieces) [901 008 MM2]

Other size on demande [901 008 ---]

The MDAC according to their use need adapted dowel guidance. It is therefore possible to need a replacement.BETSA® provides these parts with the MDACs but also replacement parts

Extractor

Extractors are simple and effective tools essential for separating the piston from the cylinder of MDAC BETSA®.

The tight fit of dowels guigances and high temperatures may cause them to require assistance in unblocking.

Made of extra hard plastic, the extractors allow parts to be separated without leaving a mark.

OUR REFERENCES

Extractor [EXT01]

Pump

If BETSA uses a pump to remove the dielectric liquid in the tank of the drill EDM [MH20M],

If BETSA uses a pump to remove the dielectric liquid in the tank of the drill EDM [MH20M], it is for 2 reasons.

The 1st is that the tank contains a few milliliters of electric oil, this amount of oil is quite large for contain the EDM dust drilling. The dusts does not focus around the drilled hole and then it is to be disseminated throughout the whole liquid which minimizes the concentration of dust and increases the quality of the sparks.

The second is to remove the liquid without using absorbent papers and to have your fingers full of it.

OUR REFERENCES

Peristalstic Pump PUMP01]

Ponc

Abrasive tool [PONC2]for electrode used in MH20 spark eroder

The small size, weight, and portability of the [PDS] allow its use in a variety of environments.

The abrasive tools have been designed to facilitate the repair (with emery cloth) of used and worn MH20M electrodes. The quality of the repair does not depend on the dexterity of the user. There is no risk of destroying (folding or folding) the tungsten part of the electrode.

OUR REFERENCES

Abrasive tool for electrode used in MH20M spark eroder) [PONC2]

Sert

Type II electrodes used with the recent (*) MH20 spark eroderare provided by BETSA(ref ELEC2).

The crimping tool is provided for users who want to make the type II electrode by themselves. (*) or old MH20 equipped with a new drilling head TP1.

Crimping length : 5 mm.

Length of the tungsten electrode: About 5 mm (can be adapted to the electrodediameter).

Making electrodes requires:

-[SERT1] tool.

-50 mm straight and rigid stainless steel capillary. (1.6mm O.D. , Adapted mm I.D.)

-One tungsten electrode. (length 10 mm)

OUR REFERENCES

Crimping tool [SERT1] for type II electrod

[SERT1]

Electrodes

the electrodes are elements for drilling gaskets in our EDM drill and are very easy to exchange

Using different diameter wires the hole diameter can be continuously varied from 60μm to 530μm by controlling the electrode voltage.

A needle is used for drilling from 10μm to 50μm.

OUR REFERENCES

List of Type II electrodes :

Electrode Needle radius 2µm. [NEEDLES2]

Electrode Ø:

50µm - [ELEC50]

80µm - [ELEC80]

100µm - [ELEC100]

125µm - [ELEC125]

150µm - [ELEC150]

200µm - [ELEC200]

250µm - [ELEC250]

300µm - [ELEC300]

380µm - [ELEC380]

500µm - [ELEC500]